The production of various products and parts involves many challenges. During production and subsequent handling, various contaminants can get on the parts, which can subsequently affect other production processes. Early detection of these contaminants can prevent problems during subsequent operations. Thanks to this, it is possible to optimize the entire degreasing process.

Discover main three benefits

Reduce scrap

and optimization

Reduces parts scrap rates by ensuring cleanliness before critical processes.

Visualisation of contamination

Visual identification of impurities and places with

the highest contamination.

Inspection of the entire surface

Possibility of checking the entire surface of the part or important points in seconds.

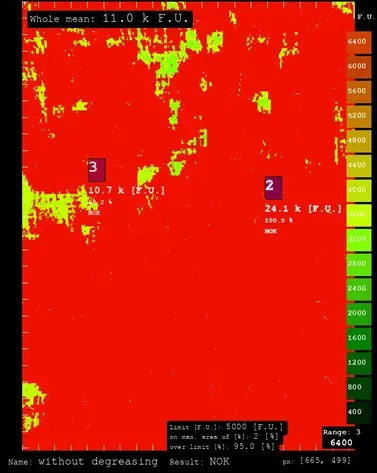

Before Degreasing

Area scanning reveals the presence of lubricant on the metal sheet before degreasing.

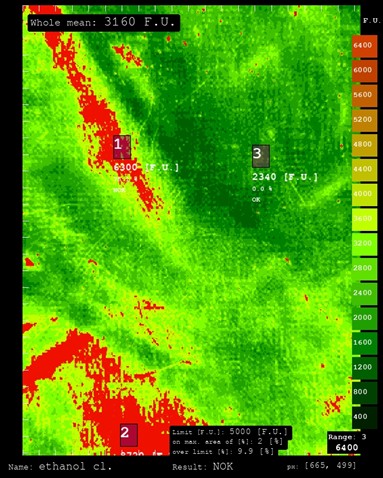

After degreasing with solvent

and dirt residues

Area scanning reveals the presence of lubricant residues on the metal sheet.

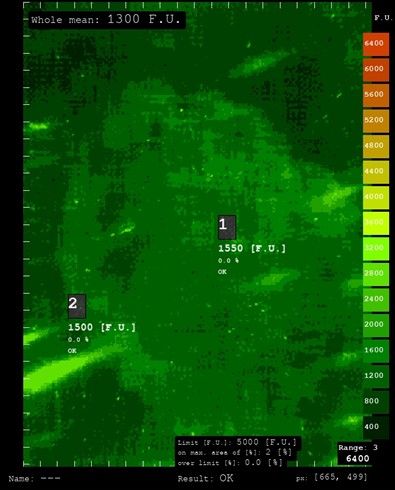

After degreasing in an ultrasonic device with solvents

Area scanning enables verification of the effectiveness of ultrasonic degreasing.

Contact Us

Have questions about Recognoil or need assistance? Our team is here to help! Whether you're looking for product details, pricing, technical support, or partnership opportunities, feel free to reach out.

Office

TechTest s.r.o.

Jungmannova 917

285 04 - Uhlirske Janovice

Czech Republic